Stormwater Quality products like the ones below are a basis of Low Impact Development, but can also be utilized in traditional stormwater management regimes. Our approach at Construction EcoServices is to look at the site in its entirety and find out what design strategy best fits the end user. Questions like “How long do you anticipate owning the property” and “How many outfalls and inlets will the property have” are critical in determining what the best course of action is and which products will perform best.

Our Stormwater Quality Treatment Products

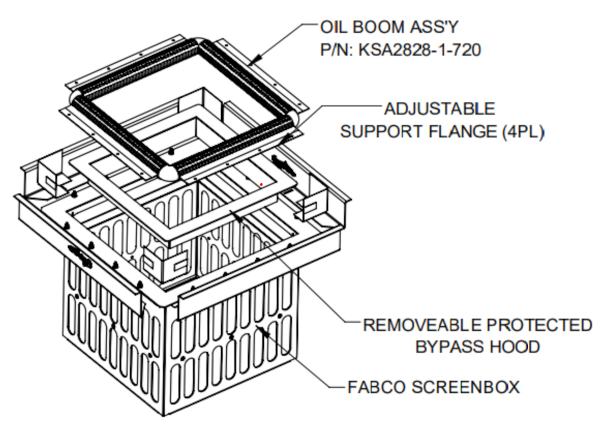

Fabco StormScreen ISB

Inlet Filter Specifically for Catch Basins

![]() “Fabco’s StormScreen ISB’s are both easy to maintain and easy to install. They typically only have to be cleaned out once a year, while other “equivalent” products (typically made of mesh) need to be cleaned far more frequently. In addition, all things being equal, Fabco StormScreen ISB’s will outlast any other solution.”

“Fabco’s StormScreen ISB’s are both easy to maintain and easy to install. They typically only have to be cleaned out once a year, while other “equivalent” products (typically made of mesh) need to be cleaned far more frequently. In addition, all things being equal, Fabco StormScreen ISB’s will outlast any other solution.”

Eli Gonzalez

Project Manager

Stormwater System Solutions

About the Fabco StormScreen ISB

The Fabco StormScreen ISB is a retrofit filter insert designed for installation into new and existing storm drain inlets or catch basin inserts. It is a new addition to the industry leading line of catch basin insert products manufactured by Fabco.

The design traps sediment and debris, all while allowing runoff water to pass through the filter and exit through the storm drain system. The Screenbox can be used for many typical applications, such as parking lots, commercial properties, roadway surfaces as well as stormwater “hot spots,” such as transportation centers, vehicle maintenance facilities, gas stations/fueling locations and industrial applications.

The StormScreen ISB frame is manufactured from high strength 5000 series aluminum to resist cracking, abrasion, and to survive severe temperature swings. The StormScreen ISB also includes quality stainless steel wire screens and an adjustable mounting system that allows you to extend or contract the support flanges to adapt to the actual site conditions.

When stormwater enters the Fabco StormScreen ISB, it passes through and over an optional oil boom that is placed around the top perimeter of the box. After this initial pretreatment, the water flows down through the protected bypass hood into the lower filtration chamber.

As the water drops down into the chamber and is filtered through the screens, the sediment and debris collected is stored in a dry state. This reduces potential septic conditions while minimizing the material weight that must be removed during clean outs – saving space and disposal costs.

After many storm events, the collected debris can weigh up to several hundreds of pounds. Clean outs can be done manually by lifting the entire unit from the drain and dumping or more rapidly by using a commercial vacuum truck.

BENEFITS

- Optimized filtration: multiple sieve size stainless steel screens enhance filtration

- Built strong: Welded aluminum frame construction

- Full capture for trash TMDL’s

- Bypass openings prevent clogging issues

- Will not impede inlet flow

- No need for confined space entry

- Easy vacuum truck servicing

SUPPORT MATERIAL

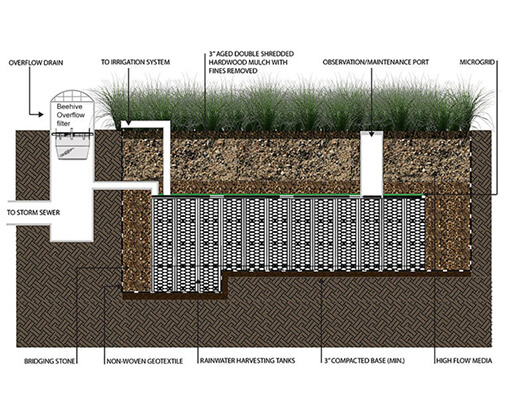

Fabco Beehive Overflow Filter

Designed for Round Manholes with Beehive or Flat Grates.

![]() “In any rain garden, some type of overflow mechanism should be considered in order to prevent erosion and other potential damage from flooding. Fabco’s Beehive, or Rain Garden Overflow Filter, is the perfect solution for this application. It can be added to capture floatables and solids in any type of round bypass or overflow structure.”

“In any rain garden, some type of overflow mechanism should be considered in order to prevent erosion and other potential damage from flooding. Fabco’s Beehive, or Rain Garden Overflow Filter, is the perfect solution for this application. It can be added to capture floatables and solids in any type of round bypass or overflow structure.”

Eli Gonzalez

Project Manager

Stormwater System Solutions

About the Beehive

Most rain gardens are designed to only capture the first inch of rain. So in any rain garden design, some type of overflow mechanism should be considered in order to prevent erosion and other potential damage from flooding.

Installing an overflow riser pipe and discharge pipe is a simple solution. However, the system needs to be protected from coarse floatables (such as mulch, organic materials and trash) that could lead to clogging and possibly flooding.

Beehive (or Rain Garden overflow) filter is the perfect solution for this application. It can be added to capture floatables and solids in any type of round bypass infrastructure.

Key Elements:

- An expansion ring (plastic or aluminum) which is sized to fit inside the riser pipe

- Geotextile filter bag with a mounting frame, and a support ring which connects the filter bag to the flange

- Quick and easy installation

Simple Installation:

- Insert the properly sized expansion ring into the riser pipe to the desired depth and clamp the ring firmly into position

- Place the assembled filter bag on top of the expansion ring

- Put the beehive grate or flat grate back on top of the riser

BENEFITS

- Simple, durable, corrosion resistant construction

- Sizes to fit most pipes: 8” up to 36” ID – short and long bags available

- Fast, simple installation – no worries about grate/frame compatibility

- Cost-effective protection for high flow operation

- Reduces clogs – keeps sediments and debris out of underground pipes

- Quick clean out –beehive filter lifts up and out for servicing

SUPPORT MATERIAL

PRODUCTS MADE FOR EACH OTHER

Fabco’s Beehive Filter can be added to capture floatables and solids in any type of round bypass infrastructure. In addition, it is often used in conjunction with underground detention/retention solutions and FocalPoint Biofiltration Systems as a key feature of the overflow drain.

Fabco Connector Pipe Screen

![]() “Fabco’s Connector Pipe Screen is a compact, affordable product that is easy to install and adaptable over a wide range of catch basin sizes and styles. The design utilizes very little space, maximizes the trash storage capacity within the catch basin and allows for easy maintenance.”

“Fabco’s Connector Pipe Screen is a compact, affordable product that is easy to install and adaptable over a wide range of catch basin sizes and styles. The design utilizes very little space, maximizes the trash storage capacity within the catch basin and allows for easy maintenance.”

Eli Gonzalez

Project Manager

Stormwater System Solutions

About the Connector Pipe Screen

A Connector Pipe Screen (CPS) is a catch basin insert filter that is designed to capture trash. Unlike other catch basin inserts that are typically installed closer to the inlet (under the drain grate or below the curb opening), CPS inserts are installed in front of the catch basin’s outlet pipe – trapping trash and debris inside the catch basin while allowing filtered stormwater to exit into the storm drain infrastructure.

CPS insert features:

- Manufactured from perforated, 14 gauge, 304 stainless steel sheets

- Perforations have a 5 millimeter diameter – screen has an open area greater than 50%

- CPS net open area (when converted to an equivalent pipe diameter) exceeds the actual diameter of the outlet pipe leaving the catch basin – CPS can pass more volume than the outlet pipe it covers

- Overflow / bypass prevents flooding if screen becomes blocked or covered

- The CPS is designed to cover a specific pipe diameter – its size does not depend on the size of the catch basin drain. The CPS is a compact, affordable product that is easy to install and adaptable over a wide range of catch basin sizes and styles.

- The design utilizes very little space, maximizes the trash storage capacity within the catch basin and allows for easy maintenance.

SUPPORT MATERIAL

PRODUCTS MADE FOR EACH OTHER

Fabco’s Pipe Connector Pipe Screen can be added to capture floatables and solids in any type of round bypass infrastructure. In addition, it is often used in conjunction with underground detention/retention solutions and FocalPoint Biofiltration Systems as a key feature of the outfall.

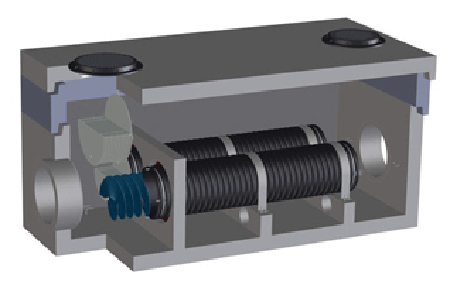

Helix

High Flow Helix Stormwater Filter for Vaults or Pipe Outfalls.

![]() “The Helix is a next generation, high-flow, stormwater filter that can be housed in a vault or installed directly into an outfall pipe. When applied with antimicrobial media, it can treat bacteria at a large scale.”

“The Helix is a next generation, high-flow, stormwater filter that can be housed in a vault or installed directly into an outfall pipe. When applied with antimicrobial media, it can treat bacteria at a large scale.”

Eli Gonzalez

Project Manager

Stormwater System Solutions

Next Generation, High-Flow, Stormwater Filter

The Helix is a next generation, high-flow, stormwater filter that can be housed in a vault or installed directly into an outfall pipe. When applied with antimicrobial media it can treat bacteria at a large scale.

Effective Two-Step Treatment Process

The Helix vault is has a two-step treatment process that incorporates an inlet chamber used to reduce clogging from sediments and debris, and a secondary treatment chamber that houses Helix’s filter elements. Coarse pollutants contained in the stormwater runoff is captured upfront – this sediment separator treats water at higher flow rates and can be serviced from the surface level with a Vac truck. The pre-treated water exiting the first chamber will keep the Helix filters cleaner, helping maintain flow rates and effectiveness while minimizing the need for maintenance.

The horizontal filter column design provides great flexibility for selecting the appropriate filter length and diameter for a given flow rate. The Helix elements inside the column(s) function as a multiple disk filter providing tremendous surface area for treatment. The spiral form offers multiple flow paths through the filter which allows the system to maintain a high flow rate while significantly reducing clogging potential.

Each Helix filter column has a designed treatment flow rate of approximately 3 cubic feet/sec. Helix filters are offered as single, double and triple column systems. Filter cartridges are replaceable and can be accessed though a standard 36″ diameter manhole provided in the vault.

Also, each Helix filter column is supplied with an inlet diffuser which is designed to keep any debris that passes through the sediment separator out of the filter column. Of course as a final precaution, each Helix also incorporates a full overflow bypass.

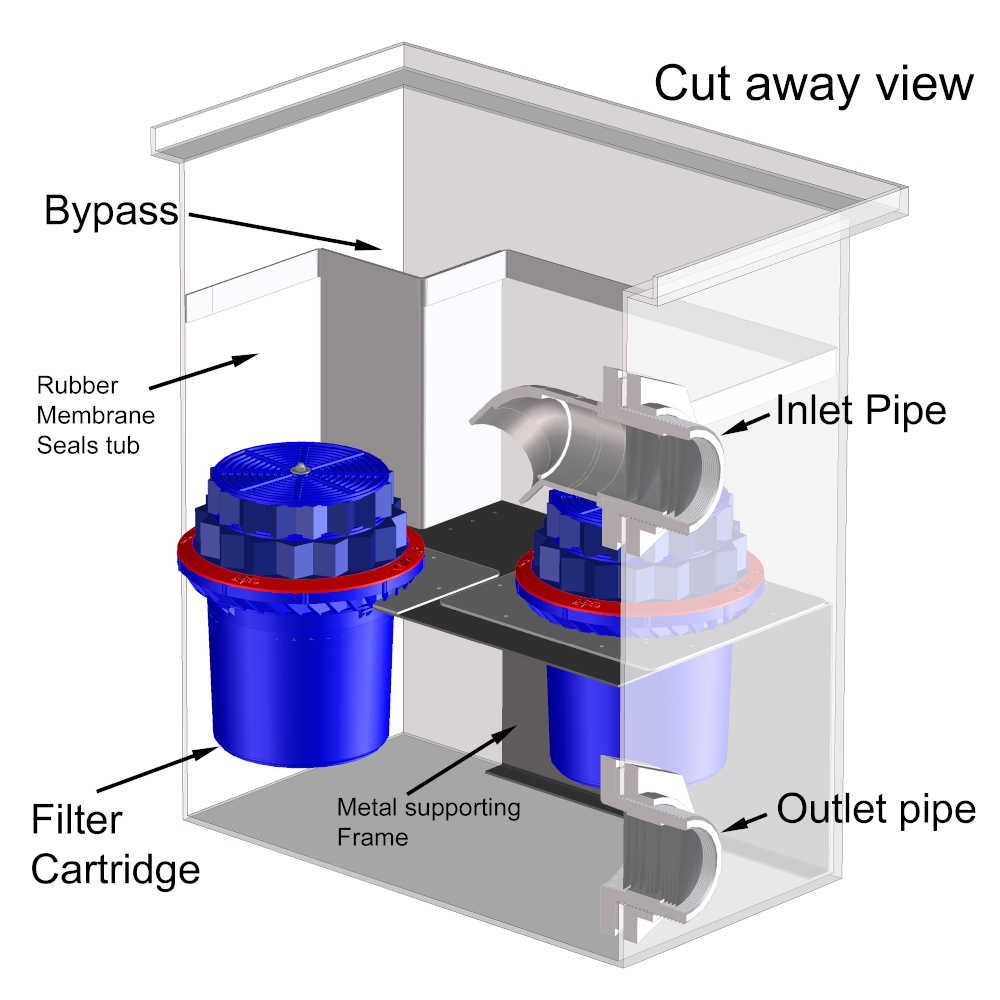

DownSpout

Treat Particulates and Soluble Pollutants

![]() “The Fabco DownSpout Filter is designed to treat particulates and soluble pollutants contained in runoff water from roof tops. This product is perfect for industrial facilities that deal with waste treatment, metal recycling, and other pollutants.”

“The Fabco DownSpout Filter is designed to treat particulates and soluble pollutants contained in runoff water from roof tops. This product is perfect for industrial facilities that deal with waste treatment, metal recycling, and other pollutants.”

Eli Gonzalez

Project Manager

Stormwater System Solutions

Applications

Heavy Metals: Stormwater can react with metal roofs, metal components or roof mounted equipment releasing soluble metals, such as zinc, copper, lead and aluminum in to the environment. Studies have shown that zinc concentrations in rooftop runoff are substantially higher than those found in rainwater. Elevated levels of zinc in soils can lead to phytotoxicity (poisoning of plant life).

Pathogens: Birds, insects, and small mammals deposit fecal matter on rooftops and in gutters, contributing bacteria and pathogens to runoff.

Hydrocarbons: Polycyclic aromatic hydrocarbons (PAHs), dust and particulate matter from vehicle exhaust and the burning of fossil fuels can collect on roof surfaces, producing elevated PAH levels in runoff.

Above Ground DownSpout Industrial Stormwater Treatment System

- Cartridge based or High Flow Geotextile filter bag system

- Large Stainless Steel filter enclosures offers multiple above ground installation and mounting options

- Hinged door panel provides easy access to filter chambers for maintenance

- 4” PVC inlet/Outlet pipes (standard)

- Select filter type:

- 2 or 3 Cartridge designs provide filter flow rates up to 520 gpm (dependent on cartridge type). Best for sediments, solids and dissolved pollutants such as: metals, bacteria, and nutrients.

- Geotextile filter bag designs are best for high treatment flow rates when the pollutants of concern are sediment, particles or other solid materials – excellent for protection of sub-surface infiltration devices.

- Built in high flow bypass

- Internal pretreatment debris screen chamber separates and keeps solid materials out of the filter cartridge area

Below Ground DownSpout Industrial Stormwater Treatment System

- Cartridge based, High Flow Geotextile filter bag, or perforated stainless steel debris basket

- All of these systems are designed to fit into large, plastic sub-surface drainage structures, typically 24”, 30 or 36” diameter

- Solid manholes or grated inlets located at grade level provide access for cleaning or maintenance

- Pipe stubs incorporated into the structures move water into and out of the filter. Various pipe diameters and entrance/exit angles can be specified for the stubs.

- Select filter type

- Systems for 2 or 4 cartridges provide flow rates between 520 and 1000 gpm (dependent on cartridge type). Best for sediments, solids and dissolved pollutants such as: metals, bacteria, and nutrients

- Geotextile filter bag designs are best for high treatment flow rates when the pollutants of concern are sediment, particles, or other solid materials – excellent for protection of sub-surface infiltration devices

- Perforated stainless steel Debris Basket systems capture particles and debris over 5mm in diameter. This is a more long term, robust solution that can be designed for inline filtration where there is no drop in elevation between the inlet and outlet pipes

ADDITIONAL INFORMATION

Fabco Filter Cartridges

Fabco’s filter cartridges are designed to provide effective treatment of stormwater while maintaining high flow rates throughout the life of the cartridge. Filter cartridges are available in various configurations allowing you to fine tune performance in terms of sediments and debris, heavy metals, hydrocarbons/toxic chemicals, pathogens/bacteria and nutrients. The lightweight filter cartridge comes fully assembled and snaps securely in place with a quick twist. The modular cartridge design allows quick and easy replacement while containing the spent material for safe transport and disposal.