FocalPoint Now Certified by Rhode Island Department of Environmental Management (RI DEM)

October 4, 2021 – The Rhode Island Department of Environmental Management (DEM) has approved the FocalPoint High Performance Modular Biofiltration System (HPMBS) — an innovative stormwater technology that is beneficial to engineers, land planners, landscape architects, installers, developers and end-users implementing green infrastructure and low impact development techniques. Because of its small footprint, open-bed configuration and modular subsurface drainage layer, it offers tremendous versatility for use as a water quality best management practice (BMP) in urban settings.

The review of the FocalPoint HPMBS application was conducted by members of the RIDEM Office of Water Resources Stormwater Technology Committee which consists of members from the Department of Environmental Management (DEM), Department of Transportation (DOT) and Coastal Resources Management Council (CRMC).

Approved technology must be designed, built, and maintained to meet the conditions specified in their technology-specific RIDEM certification letter. Pollutant removal rates assigned to the FocalPoint HPMBS include the following: 85% of total suspended solids, 30% of total nitrogen, 30% of total phosphorus, and 60% of pathogens.

FocalPoint HPMBS was developed by Convergent Water Technologies and sold locally through Ferguson Waterworks, a member of Convergent’s value added reseller network.

FOCUS ON THE BENEFITS

SPEND LESS.

Build More.

LOOK BETTER.

Spend Less. Build More. Look Better.

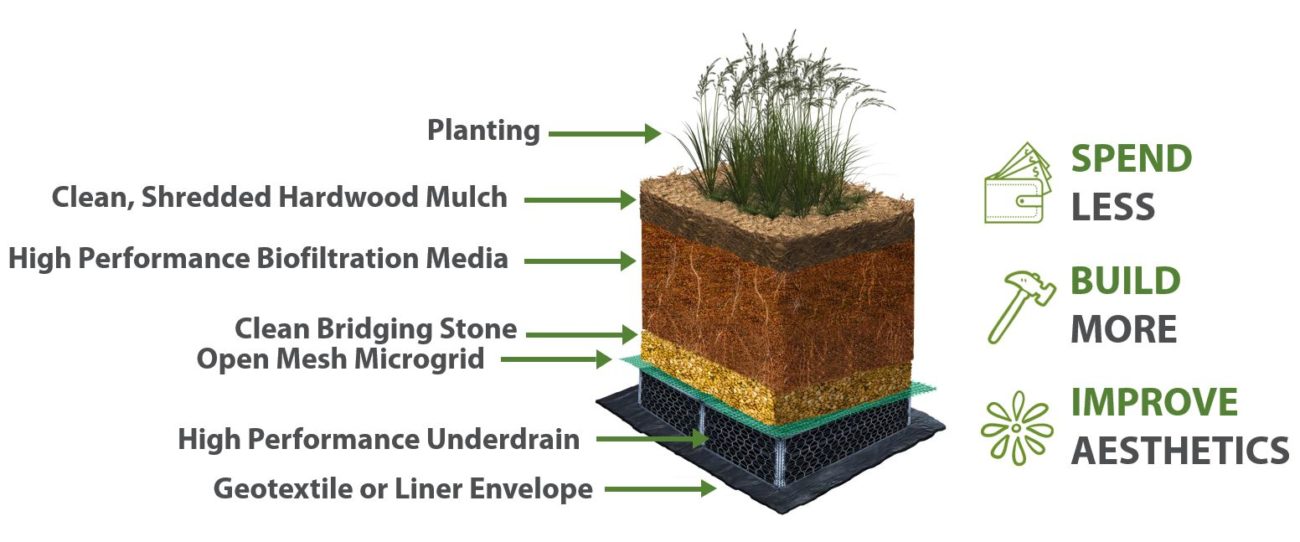

FocalPoint High-Performance Modular Biofiltration System (HPMBS) is a scalable biofiltration system which combines the efficiency of high flow rate engineered soils with the durability and modularity of a highly pervious expandable underdrain/storage/infiltration system. The modular FocalPoint HPMBS is a complete, integrated system with a demanding specification that insures functionality, performance and maintainability. With rigorous quality assurance standards and post-construction in-situ performance verification, FocalPoint HPMBS provides guaranteed performance.

The FocalPoint’s modular underdrain, unlike a traditional perforated pipe, not only supports the flow rate of the media, but can be expanded beyond the footprint of the media bed to provide unlimited underground detention, infiltration and/or storage for water reuse/infiltration.

FocalPoint HPMBS gives designers maximum flexibility in meeting both water quality and volume requirements.

The system can be used in combination with traditional LID BMPs such as grassy swales and vegetated depressions. It enables implementation of green streets using urban sidewalk planters; which because of the small footprint can support designs with large trees. These systems are also used for downspout planters, replacing underground treatment systems and are an easy retrofit for failed traditional bioretention systems. FocalPoint provides unlimited application opportunities for new construction and redevelopment.

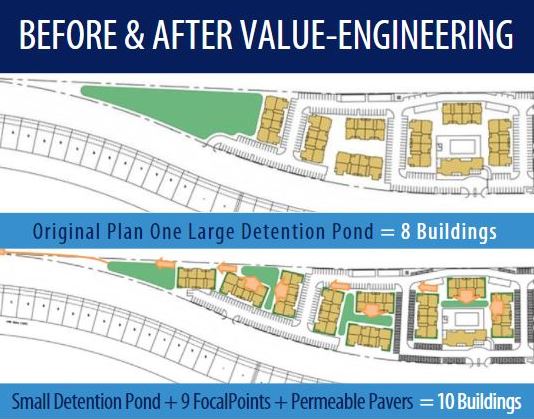

In addition, when used in conjunction with complimentary stormwater management solutions, such as bioswales, permeable pavement, and raingardens, FocalPoint creates the ability for developers, architects and engineers to decrease a property’s surface storage volume requirements and increase lot yield. Subsequently, more land can be developed, increasing long-term revenue and property value.

Although the price per square foot of FocalPoint is many times higher than traditional bioretention, the efficiency of the FocalPoint High Performance Media makes the system more than 30 times smaller, per acre treated, resulting in a 50% cost savings per acre treated. The first year’s maintenance is included in all FocalPoint HPMBS installations to ensure that the system is given the best opportunity to succeed, and low cost annual maintenance contracts are available.

Due to the efficiency of the FocalPoint media, scale is in its favor. Fulfilling equal requirements, a FocalPoint solution will use 30x less space than a detention pond solution.

Time-lapse Video

Watch FocalPoint

Being Built

- Build more – decrease a property’s surface storage volume requirements and increase lot yield.

- Spend less – FocalPoint is more than 30x smaller, per acre treated, resulting in a 50% cost savings.

- Look better – unlimited application and beautification opportunities for new construction and redevelopment.

- More flexibility – reap the advantages of a highly pervious expandable underdrain/storage/infiltration system

![]()

Proof Is In The Performance

FocalPoint utilizes physical, chemical and biological mechanisms of a soil, plant and microbe complex to achieve pollutant removal rates consistent with traditional bioretention, and the option of increased removal characteristics for specific pollutant targets.

![]()

Increase

Build More, Increase Property Value &

Enhance Aesthetics

A FOCALPOINT CASE STUDY

Project Background

Queenston Manor Apartments sits on a 7.2 acre parcel of land located adjacent to a master planned community on Houston’s northwest side. When Academy Development originally planned the construction of an apartment complex on this site, the economic model required that nine apartment buildings be built in order to generate the required revenue stream. Operating under the premise that all of their detention had been accounted for offsite in the surrounding master planned development, the project came to a screeching halt when it was determined by the County that the volume presumably set aside was no longer available for use by the apartment site. The engineers at EHRA, Inc. rescued this project with Low Impact Development (LID) and the FocalPoint High Performance Modular Biofiltration System (HPMBS),

Why Use Low Impact Development?

Faced with the harsh reality that this project might no longer be viable due to the amount of site area which would otherwise be lost to a detention pond, the engineering firm of Edminster, Hinshaw, Russ and Associates (EHRA) asked Academy Development if they would be open to a Low Impact Development-based design. The objective would be to reduce peak flows and thereby decrease total detention volume under Harris County’s LID Design Guide which requires post and pre-development hydrograph matching. Doing so would allow the developer to recapture the real estate that would have to be occupied by detention facility in the traditional design, and make the site viable for apartment construction once again. EHRA redesigned the project with extensive use of porous pavers in parking stalls, a directly infiltrated underground detention system fed by the porous paver system, vegetated swales and vegetated depressions throughout the common areas which drain through a series of small, decentralized FocalPoint HPMBS. The design team was able to decrease the surface storage volume requirements for the property enough to reclaim the property needed to build two additional apartment buildings and save the project. For the developers, the 48 additional apartment units meant the difference between success and a cancelled project.

FocalPoint High Performance Modular Biofiltration System (HPMBS)

The FocalPoint HPMBS is a combination of a high performance, open cell underdrain, a clog-proof bridging mesh, bridging stone, and a high performance biofiltration media that flows at a rate of over 100” per hour. What this unique combination of parts creates is a system that provides unsurpassed water quality and drainage characteristics. For the purpose of Queenston Manor Apartments, reliability was an important element in that all of the drainage areas are also common areas and courtyards. It was imperative that the system could be relied upon to drain as designed so that within 24 hours of a rain event, there would be no standing water. By placing the HPMBS at the lowest elevation in the four landscaped swale systems on site, we were able to give Queenston Manor a reliable drainage and water quality solution.

Quality Solutions

The Queenston Manor Apartments boast extraordinary amenities including a full service bar on site as well as an infinity pool. One of the most impressive and unique features of the site, however is the use of Low Impact Development practices throughout the property.

Resources

Documentation

If there is other documentation not posted here, pleas contact us and we will be happy to provide any additional specs or technical information you need.

Get In Touch

If you and your team would like to learn more about any of the wide variety of products and services we offer, schedule a LOUNGE & LEARN today. We can discuss with your team anything from our turnkey compliance services during construction activity to our post-construction stormwater management systems; or our stormwater quality treatment to our erosion and sediment control solutions.

FocalPoint FAQs

Is FocalPoint Certified in Rhode Island?

If you are looking for an Approved Biofiltration System in Rhode Island, look no further.

FocalPoint (High Performance Modular Biofiltration System) is recognized by the Rhode Island Department of Environmental Management (DEM) and Coastal Resources Management Council (CRMC) for use as a water quality BMP or pretreatment device for site development projects and as a retrofit device for redevelopment projects.

The FocalPoint is approved in Rhode Island for the following pollutant removals when designed with the maximum infiltration rate of 100 inches per hour: 85% removal of total suspended solids (TSS), 60% removal of pathogens, 30% removal of total phosphorus (TP) for discharges to freshwaters, and 30% removal of total nitrogen (TN) for discharges to tidal waters.

Design Questions

FocalPoint systems are typically sized as a percentage of the impervious drainage area that contributes runoff to the system. The specific percentage varies by state, but 175 square feet per impervious acre is usually a good estimate. Some states use routing methodology (such as TR-55) to design systems. Contact us if you would like help with these designs.

Traditional bioretention systems filter runoff at a much slower rate than FocalPoint, which means they need far more square footage to treat the same amount of runoff. These traditional systems typically filter runoff at 1-4 inches/hour/square foot, while FocalPoint filters runoff at over 100 inches/hour/square foot.

Using a mini excavator, preparing a 4’ x 5’ excavation is manageable, so we typically use 20 square feet as the minimum size. We have built systems as small as 12 square feet (3’ x 4’), but there is significantly more hand-work involved to get the dimensions precise.

There is no maximum size, but be mindful of managing energy dissipation and flow velocities entering the FocalPoint.

FocalPoint systems should be modelled to flow at 100 inches per hour.

If the runoff treated by FocalPoint needs to be infiltrated after treatment, it is possible to do that either directly beneath the FocalPoint, or in a separate infiltration bed/basin (assuming there is enough elevation/depth above the SHWT). It is frequently possible to infiltrate directly beneath the FocalPoint by increasing the height of the high-performance underdrain, expanding the underdrain outside of the FocalPoint media footprint, or both.

FocalPoint is a sustainable, living system that should not need to be deconstructed, rebuilt, or replaced. However, in rare instances where regular maintenance does not restore water flow through the system, replacing the top 3” – 6” of the media bed will typically restore the system to its original capabilities. Contact us for guidance on confirming your restoration plan.

The standard depth for FocalPoint is 42.5” from flowline to the invert of the outlet. This includes 6” ponding depth, 3” of mulch, 18” of media, 6” of bridging stone, and the 9.5” underdrain. It is possible to modify the profile to reduce the overall depth when necessary.

There are two options to consider when dealing with depth limitations. It is possible to either reduce the overall depth of the system or to add an impermeable geomembrane envelope to the system. Contact us to explore the options.

Typical ponding depth in a FocalPoint system is 6”, and many systems have been built with 12” ponding depths over the FocalPoint. However, it is possible to have much deeper ponding areas with FocalPoint. Successful installations have been constructed with ponding depths as great as 60”. contact uscan help with non-standard applications.

The grading around a FocalPoint should be no different than traditional bioretention systems. This includes side slopes no greater than 3:1, and the inclusion of energy dissipation at any areas of concentrated flow. For steeper grades in tight spaces, there are several options that can be explored, such as the use of Turf Reinforcement Mats, decorative stone, short curbs, and a variety of other options. Contact us about options that will work best for your site.

Most systems don’t require a border. However, in some cases, borders can be useful for energy dissipation as well as delineation of the system. There are multiple ways to handle both of these objectives, contact us for help identify the best solution for your project

In most states and localities, upstream pretreatment is not required. However, that doesn’t mean it’s not a good idea! Good pre-treatment facilitates future maintenance and will pay for itself quickly. Consider using the Rain Guardian Turret for smaller drainage areas and PreTx for larger ones.

Yes! Because FocalPoint uses an open, generic, performance-based specification, it can easily be used on all types of projects where proprietary devices are prohibited.

The FocalPoint system has been approved and installed in more than 25 states and the District of Columbia. While not all states maintain an “Approved Products” list, FocalPoint has been approved as a stand-alone treatment practice for new construction, retrofit and redevelopment projects in CT, DE, MA, MD, ME, NH, NY, PA, VA and many others. Contact us for permitting and approval assistance.

Costs vary based on the size and location of the job. Experience has shown that FocalPoint costs are similar to traditional bioretention systems that treat the same volume of runoff, with the added benefit of a drastically smaller footprint and the resulting reduced maintenance costs of the smaller footprint. Contact your local ACF Environmental representative for local pricing.

Cities, Counties, Regional and State permitting authorities across the country, in at least 25 states and the District of Columbia, have permitted FocalPoint installations, including states that don’t have an ‘approved products’ lists. States which do have an innovative technology/products list, and in which FocalPoint has been accepted as a stand-alone water quality BMP or primary treatment practice include CT, DE, FL, MA, MD, ME, NH, NY, OH, PA, VA, VT and WV.

The FocalPoint system has been approved and installed in more than 25 states and the District of Columbia. While not all states maintain an “Approved Products” list, FocalPoint has been approved as a stand-alone treatment practice for new construction, retrofit and redevelopment projects in CT, DE, MA, MD, ME, NH, NY, PA, VA and many others. Contact us for permitting and approval assistance.

Components Questions

The media components are listed in the specification and are not proprietary. The only secret of FocalPoint is in consistently building systems that exceed the performance-based specification used in the design.

h.

All components, including mulch, media, and bridging stone, are typically shipped in supersacks to avoid contamination from on-site soils. The structural underdrain is typically shipped on pallets, along with any other components that may be necessary for your project.

FocalPoint is sold exclusively as a complete system. The components have been tested together to guarantee compatibility, prevent problems, and ensure the installed system meets the performance specification.

Yes! Plants are a critical component, and they help ensure the long-term performance of the system. Plant roots help create pathways for water to flow, and they pull nutrients from the soils, recharging the media and allowing it to continue to treat runoff. Read the Plant Selection tech note for additional information on what plants work best in the system.

Construction EcoServices does not provide the plants. Refer to the Plant Selection tech note for additional information on plant spacing and plant varieties, or consult with a local landscape architect or nursery provider to source plants well-adapted to a bioretention environment.

All of the mulch supplied with FocalPoint Systems has been screened through a trommel to remove the fine particles. These fine particles can plug up bioretention systems and negatively impact the flow of runoff through the system. Outside mulch sources and bagged mulch from home improvement stores should not be used in a FocalPoint system.

Construction EcoServices will provide a year of maintenance (including replacement mulch) after the system is installed at no cost. After that, owners or their maintenance contractors can purchase mulch through Construction EcoServices, or they may be able to find alternative sources of screened mulch. We never recommend using bagged mulch.

When installed along the curbline, traditional curb inlets are ideal for the bypass structure. When drop-inlets are used, flat grates should be avoided and domed or slanted grates should be used. These grates shed mulch and debris as ponded water recedes to prevent clogging of the overflow.

In some cases it is possible, even necessary, to reduce the thickness of the bridging stone layer. Contact us to explore this possibility.

Incompatibility between filtration medias and bridging materials is a common reason for failure of traditional bioretention systems. Construction EcoServices has done modelling, lab testing, and field testing to ensure the bridging stone supplied with the FocalPoint system is an ideal match to properly bridge the media.

ch.

When used, Gabions typically sit within the FocalPoint footprint just below the top of the media. The gabion remains completely permeable, so flow through the system, including the media below the gabion, is unaffected.

No, the gabion border is not required and should only be included when needed for delineation or energy dissipation. Delineation of the FocalPoint can be useful when the system is installed in a larger landscaped area that looks uniform once mulch is applied, but it is not necessary if turf or other materials are used around the system that make the maintenance area obvious. Energy dissipation can be a useful function of the gabion, but other systems such as the Rain Guardian or PreTx are better suited for this purpose.

Perforated pipes usually have 2-5% of their surface area open for water to move into the pipe. This limitation restricts flow and prevents the FocalPoint system from operating at its maximum efficiency. The high-performance underdrain that comes with FocalPoint has a surface that is 90% open area, allowing for much greater flow through the system.

The underdrain should only receive runoff that has been treated by the FocalPoint system, so no maintenance of the underdrain should be necessary. Overflow structures should be located on the outlet side of the system to avoid introducing untreated water directly into the underdrain. If access to the underdrain for maintenance is critical to your project, contact us for options to include this capability.

<p>The underdrain supplied with the FocalPoint must be used to ensure the system performs as specified, and other options must be avoided. Construction EcoServices provides multiple underdrain depth options to ensure there is a good fit for every type of project. <a href=”https://www.constructionecoservices.com/contact/sales/” target=”_blank” rel=”noopener”>Contact us</a> for more information about the underdrain options available to you.</p>

No geotextiles are used in the operational cross-section of the FocalPoint, as these fabrics have a history of clogging in bioretention applications. FocalPoint does incorporate different geosynthetic materials to form the outer envelope of the system, and there are specific recommendations to mitigate clogging when infiltration of runoff from the system underdrain into the surrounding soils is desired.

There are three different materials that can be used to form FocalPoint’s outer envelope based on the design goal of the system.

- Nonwoven Geotextile: Appropriate for most systems, the standard nonwoven geotextile envelope will protect the system from the backfill materials while remaining permeable, allowing some of the treated runoff to infiltrate into surrounding soils.

- Woven Monofilament: Used when infiltration is required, this material has larger openings than the nonwoven material, which helps mitigate clogging.

- Geomembrane: Used to prevent infiltration, geomembranes (typically 30 mil PVC) retain all water within the system when issues like karst, groundwater contamination, or soil contaminants are a concern.

Geotextiles are used to form the outer envelope of the system, but not within the operation cross-section. A microgrid separates the bridging stone from the structural underdrain, and its larger openings are not susceptible to clogging like a geotextile would be.

Installation Questions

Many excavations are oversized or done to rough measurements, but FocalPoint excavations must be done to precise measurements with no additional area excavated. This is critical since components are supplied in the exact quantities necessary to fill the excavation, with limited waste factors included.

There is no special certification needed to install a FocalPoint system. All of the steps are fairly simple and similar to construction of a traditional bioretention system. However, working in smaller spaces with precise requirements can be tricky, and Construction EcoServices can provide recommendations for installers that have successfully built many FocalPoint systems if desired.

Construction EcoServices will conduct a pre-construction meeting at no additional cost and will be on-site as much as possible to ensure a successful installation.

FocalPoint uses a performance-based specification that requires the installed system to perform at the specified standard. After installation a hydraulic conductivity test is performed at no additional charge to ensure the system is functioning properly. This testing is typically done 30-90 days after installation.

Maintenance requirements for FocalPoint are similar to those for traditional bioretention. Mulch should be removed and replaced every 6-12 months, and plants should be trimmed back to encourage growth (and the consumption of nutrients). Read the Operations & Maintenance Guide for more information.